|

Dijital baskı teknolojilerinde Epson firmasının ürettiği yazıcıları ve baskı kafalarını günümüzde en az bir kere herkes kullanmıştır. Baskı makinesi olmayanlar en azından evlerinde yada ofislerinde yazıcı olarak Epson makineleri kullanmıştır.

Reklam sektöründe uzun yıllardan bu yana Epson kafa kullanan bir çok makine mevcut, örneğin Epson’un kendi ürettiği makineler haricinde ROLAND, MIMAKI, MUTOH, vb makineler bu kafaları kullandılar. Son yıllarda Uzak Doğu (Çin) da üretilen bir çok ufak ölçekli makinelerde bu kafalar kullanılmaya başlandı.

Tabiki piyasamızda Epson DX5 (F186000) adı ile anılan kafa daha çok bilinen bir model. İlerleyen zamanlarda Epson firması birçok farklı kafa modelini kendi yazıcılarına koyup piyasaya sundu, uzak doğudaki makine üreticileri bu kafaları kendi ürettikleri makinelere ekleyip daha ucuz, daha hızlı, makineler ortaya çıkardılar, bu duruma bazen Epson firması kafalara KOD ekleme yaparak ayak diredi, fakat sonuç olarak hala Epson kafalı makineler görevlerini yerine getirmeye devam ediyorlar.

Biraz daha teknik olarak duruma bakarsak.. Baskı kafalarındaki DX-*** / EPS*** / WF*** gibi kodlar EPSON firmasının kullandığı kodlar değildir. Fabrika F*** gibi kodlar kullanıyor.

Piyasadaki DX-TX gibi isimler kafanın ilk takıldığı yazıcının model numarası, yada uzak doğudaki makine üreticilerinin verdiği isimlerdir.

Ülkemizde yada Yurt dışında makine satışı yapan firmalardan DX-12-13,14,15,16,17……gibi sürüp giden isimler duyabilirsiniz. Rakam yükseldikçe kalite ve hız artar diye bir kural yok.

Örneğin XP-600 (Masa üstü yazıcısının model numarası ) 6 Renk bir kafaya genel olarak DX-9 ve DX-11 isimleri takılmış, ama başka bir satıcı bu kafaya DX-13 ya DX333 de diyebilir.

Makinenin uzun soluklu çalışması için , Epson kafa kullanan makinelerde baskı kafa haricinde diğer aksamlar ve satıcı firmanın teknik bilgi ve becerisi de önemli bir etkendir.

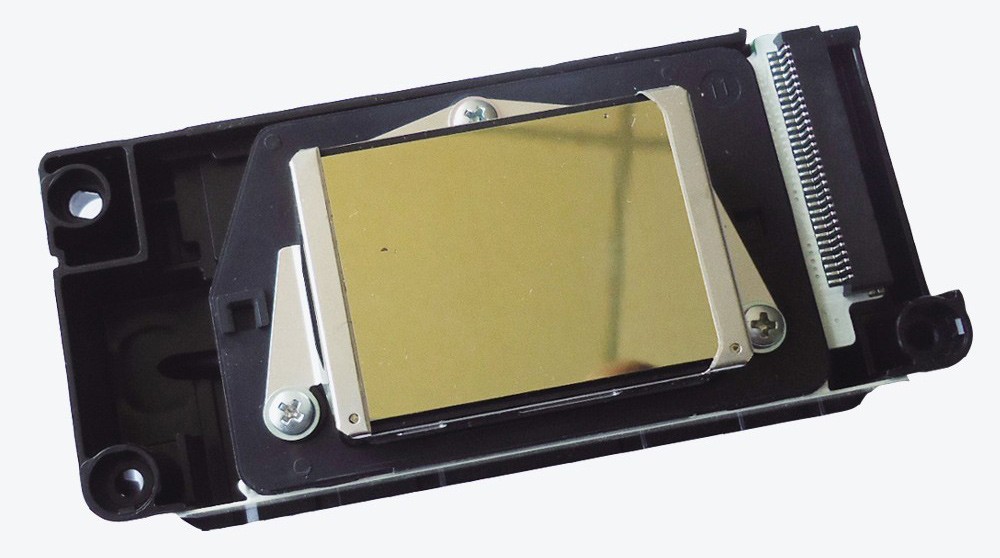

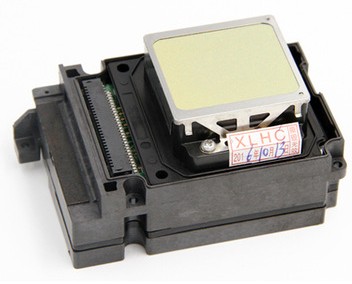

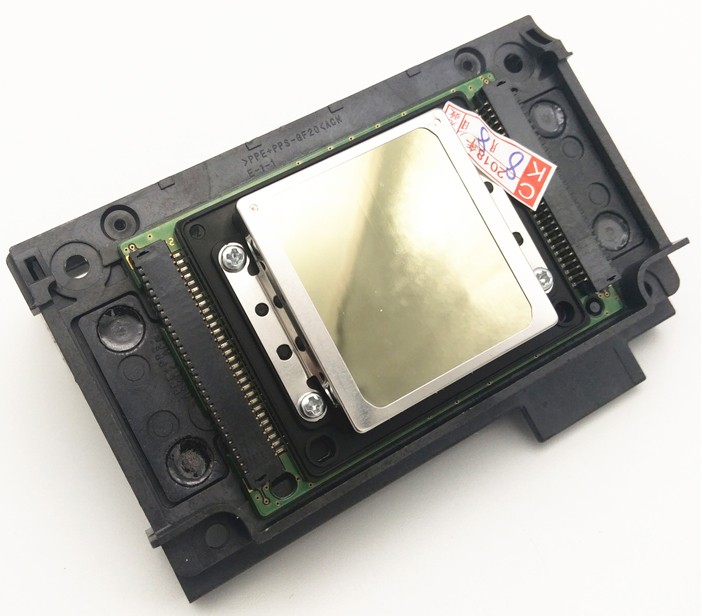

| Genel bilinen isimler | DX5 | DX6 | DX7 | DX8-DX10 | DX9-DX11 | EPS3200 |

| Kafa Resimleri |  |

|

|

|

|

|

| Fabrika Kodu | F186000 | F191010 | F189000 | F192040 | FA09000 | WF-4720 |

| Diğer isimleri | TX-800 | XP600 | Tekstil: 5113 | |||

| Renk desteği | 8 Kanal | 10 Kanal | 8 Kanal | 6 Kanal | 6 Kanla | 4 Kanal |

| Nozzel sayısı | 1440 | 3600 | 1440 | 1080 | 1080 | 3200 |

| Desteklediği boya | ECO SOLVENT – TEKSTIL – UV | |||||

| Bilgilendirme | En çok kullanılan kafalardan bir tanesi | Roland,Epson gibi makineler kullandı | DX5 Kafadan sonra piyasaya çıktı, | Ömrü kısa, ucuz bir kafa | Dx5, Dx7 den %20 daha hızlı, daha ucuz | Dx5,Dx7 den %30 daha hızlı |

|

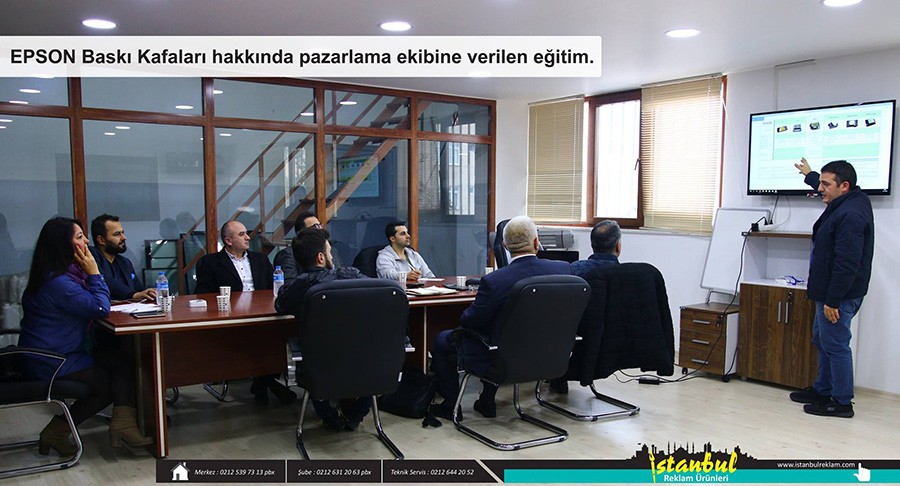

| Epson baskı kafaları hakkında pazarlama ekibine verilen seminer… (19-11-2018) |